النايلون، المعروف بمتانته ومتانته ومقاومته الممتازة للتآكل، يُعدّ منذ زمن طويل حجر الزاوية في مجال البلاستيك الهندسي. ومع ذلك، فإن عيوبه—مثل امتصاص الرطوبة العالية، والاستقرار الأبعادي المحدود، واستهلاك طاقة المعالجة المرتفع نسبيًا—لا يمكن تجاهل هذه القيود. وللتغلب على هذه القيود، ركز الباحثون على مزج النايلون مع راتنجات أخرى لتحسين أدائه. ومن بين مختلف الأنظمة، تُعدّ سبائك PA/PP وPA/ABS الأكثر تمثيلاً، حيث تحقق تكاملاً في الأداء من حيث القوة والمتانة والمقاومة الكيميائية والفعالية من حيث التكلفة.

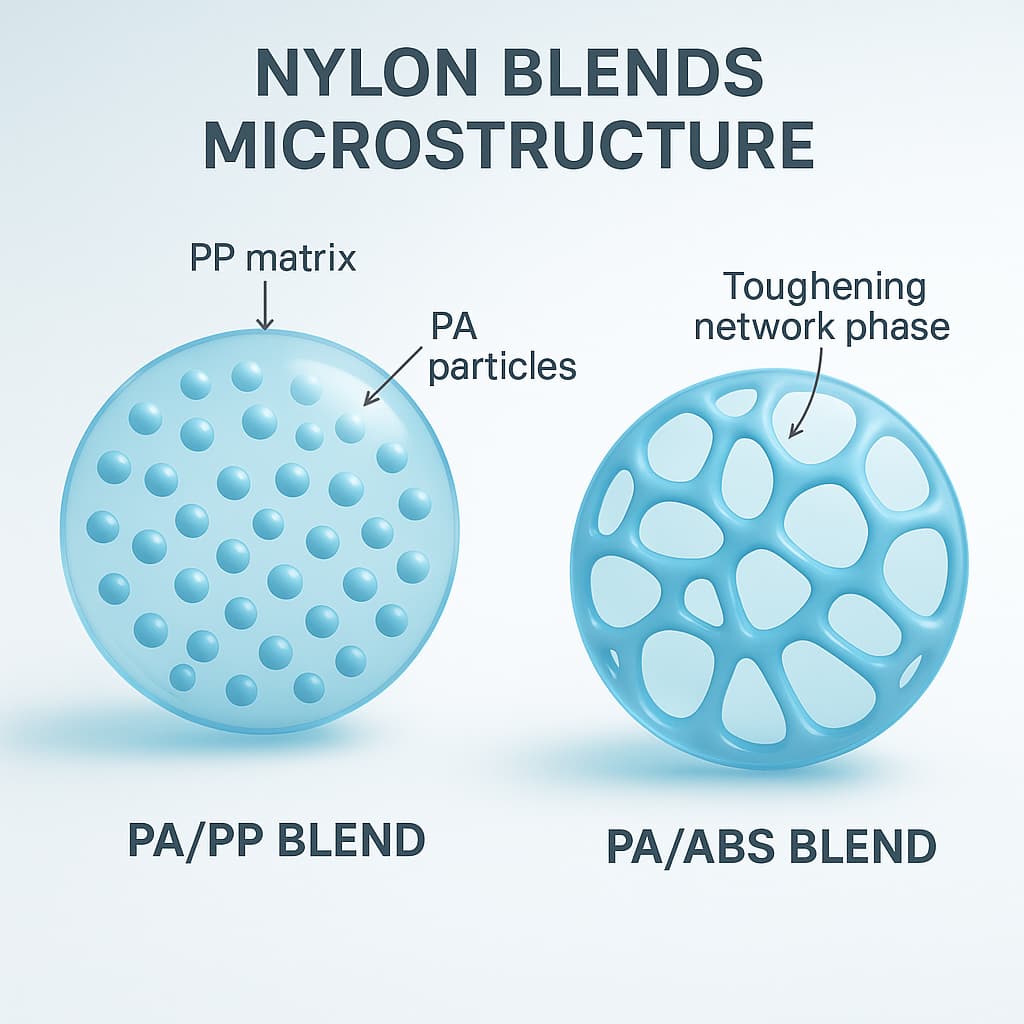

في مخاليط PA/PP، يساهم النايلون القوة ومقاومة الحرارةفي حين يوفر البولي بروبلين امتصاصًا منخفضًا للرطوبة، وثباتًا كيميائيًا فائقًا، ومزايا من حيث التكلفة. يكمن التحدي الرئيسي في ضعف التوافق الناتج عن اختلافات القطبية. ولحل هذه المشكلة، تم طرح مواد توافقية مثل البولي بروبيلين المطعم بماليك أنهيدريد (PP-g-MA). تُمكّن هذه المواد التوافقية من تشتت أدق للطور، مما يُحسّن مقاومة الصدمات وثبات الأبعاد مع تقليل امتصاص الماء. ونتيجةً لذلك، تُستخدم سبائك PA/PP على نطاق واسع في دواخل السيارات، والمصدات، وأغطية الأجهزة، حيث تجمع بين المتانة وخفض التكلفة.

على النقيض من ذلك، تركز مخاليط PA/ABS بشكل أكبر على تحسين الصلابة. يوفر النايلون قوة عاليةفي حين توفر مادة ABS مقاومة ممتازة للصدمات، مما يجعل التركيبة مثالية للأجزاء التي تتطلب كلتا الخاصيتين. المواد المتوافقة مثل الستايرين–تلعب بوليمرات أنهيدريد الماليك (SMA)، أو ABS المُطعّم بأنهيدريد الماليك، دورًا حاسمًا في تقوية الترابط بين السطوح، مما يُحسّن امتصاص الطاقة تحت الضغط. وتتراوح تطبيقاتها بين المعدات الرياضية والمكونات الإلكترونية والأجزاء الهيكلية، حيث يُعدّ الأداء الميكانيكي المتوازن أمرًا بالغ الأهمية.

تُعد مزايا المعالجة ميزة أخرى لسبائك النايلون. غالبًا ما يعاني النايلون الخالص من الانكماش والتشوه وعدم الاستقرار البعدي بسبب امتصاص الرطوبة أثناء عملية القولبة بالحقن. يُقلل مزجه مع البولي بروبيلين أو الأكريلونيتريل بوتادين ستايرين (ABS) من هذه المشاكل بشكل كبير، مما يُحسّن استقرار القولبة وكفاءة الإنتاج. بالنسبة للمُصنّعين، يُترجم هذا إلى انخفاض معدلات الخردة وزيادة العوائد الاقتصادية.

في المستقبل، سيركز تطوير سبائك النايلون على الاستدامة وتعدد الوظائف. قد يحل البولي بروبيلين الحيوي أو ABS المتجدد محل الراتنجات التقليدية لتحقيق الأهداف البيئية، بينما يمكن استخدام مثبطات اللهب، والحشوات الموصلة، أو الألياف المقوية لتوسيع نطاق التطبيقات. يتماشى هذا التطور مع التوجهات العالمية نحو مواد صديقة للبيئة وعالية الأداء للسيارات الكهربائية، وأجهزة اتصالات الجيل الخامس، والتصنيع الذكي.

في الختام، تُمثل سبائك PA/PP وPA/ABS أكثر من مجرد حل وسط؛ فهي تُجسد تكاملاً حقيقياً في الأداء بفضل التوافقيات والمعالجة المتقدمة. من خلال الجمع بين النايلون’بفضل قوتها ومتانتها المحسنة، وامتصاصها المنخفض للرطوبة، واستقرارها المعزز في المعالجة، تضمن هذه السبائك دورها الذي لا غنى عنه في الصناعة الحديثة.